ATTRIBUTE

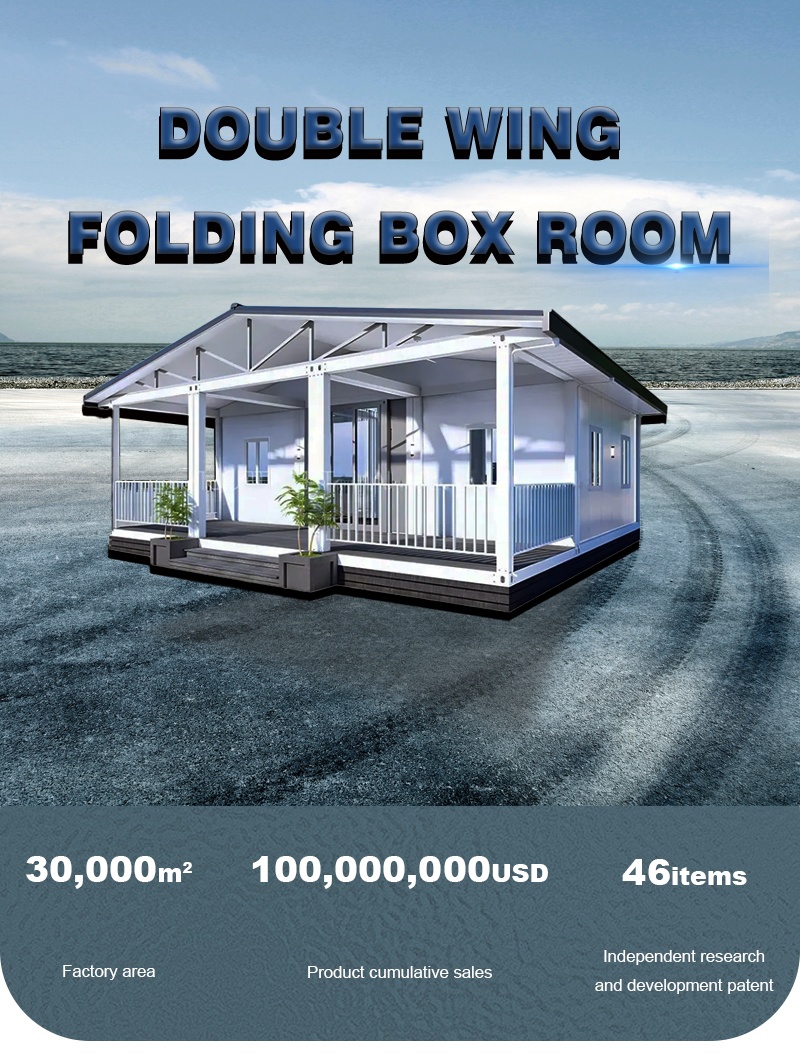

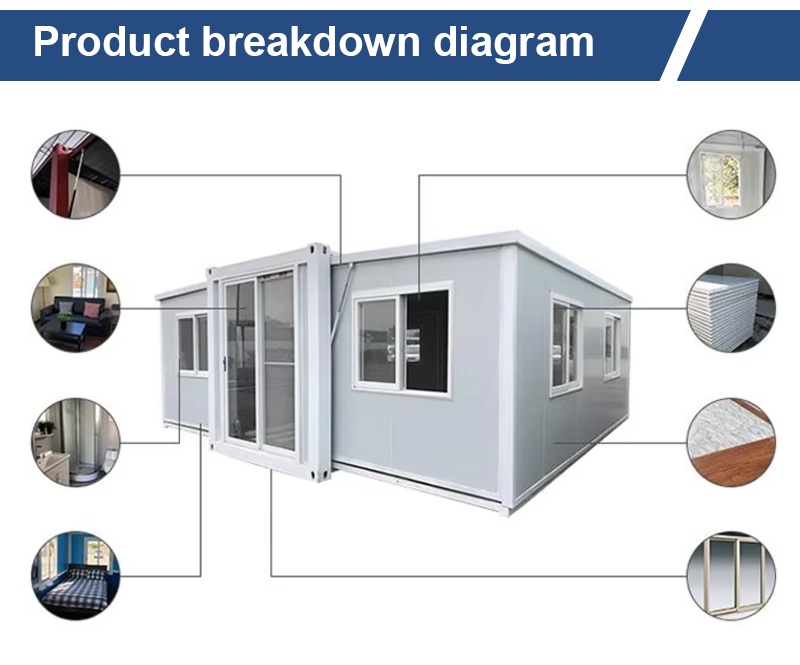

Box size(L*W*Hmm): L11800*W6220*H2480mm Internal size(L*W*Hmm):L11540*W6060*H2200mm Folding size:L11800*W2200*H2480mm Building area:72㎡ Structure material:galvanized cold rolled steel (SGH340) full galvanized square tube Frame coating: electrostatic spraying / straight white plastic powder coating Thermal insulation structure: 65mm high-level bamboo carbon fiber insulation composite panel Box roof material: t50mm thickness EPS color steel plate / corrugated veneer t0.4mm floor material: fire cement fiber floor 18mm thick Fire rating: flame retardant B1 grade Ground load: 1.5KN/m² Roof Load: 1.5KN/m2 Wind load: 0.6KN/m² Insulation factor: >R3.5 Structural life: 30 years

PRODUCT DESCRIPTION

| Product name: | Expandable folding room |

| advantage: | Environmental protection,fast installation, and cost reduction |

| service life: | At least 30 years |

| size: | customized |

| structure: | light steel frame |

| floor: | MGO board, fiber cement board, PVC board |

| Steel material: | SGH340.Q235B.Q195B |