Research on the application of assembly design for temporary housing buildings on construction sites

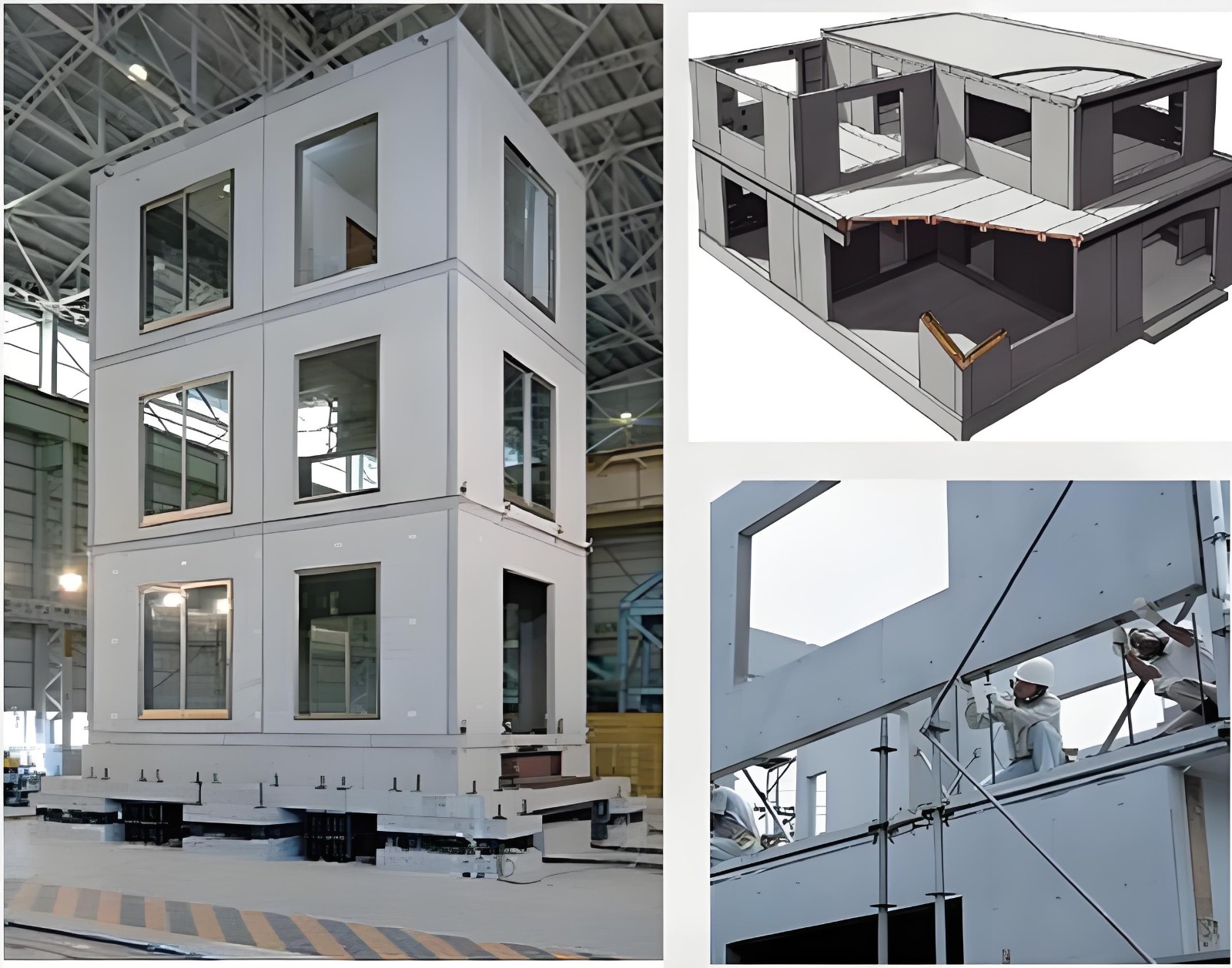

Contents: Factory prefabricated components: most of the components of the assembled temporary housing are standardised in the factory, the production process is not restricted by on-site construction conditions, and multiple components can be produced at the same time, which greatly improves the production efficiency.

Rapid on-site assembly: After the prefabricated components are transported to the construction site, only simple assembly is required to complete the construction of the house. Compared with traditional on-site construction methods, assembly design can greatly shorten the construction cycle and reduce the impact of construction time on the project progress.

Standardised production: The prefabricated components produced in factories adopt standardised production processes and quality control systems, ensuring stable and reliable quality. Compared with traditional on-site construction, assembly design can reduce the impact of human factors on construction quality and improve the overall quality level of housing.

Good structural stability: assembled temporary housing usually adopts light steel structure, containers and other structural forms, which have good structural stability and anti-seismic performance. In complex construction environments such as construction sites, it can provide a safer and more reliable living environment for construction workers.

Recyclable materials: Most of the components of the assembled temporary housing are made of recyclable materials, such as steel and wood, which reduces the consumption of natural resources. After the house is dismantled, these components can be recycled and reused, reducing the generation of construction waste and meeting the requirements of energy saving and environmental protection.

Good energy-saving performance: assembled temporary housing can use advanced thermal insulation materials and energy-saving equipment to improve the energy-saving performance of the house. In the process of use, it can reduce energy consumption, lower operating costs, and bring economic benefits to construction companies.

Strong mobility: assembled temporary housing can be moved and disassembled according to the progress of the project and construction needs. At the end of the project, the housing can be dismantled and transported to other construction sites for further use, which improves the utilisation rate of the housing and reduces construction costs.

Easy to transform and expand: the structural form and component design of the assembled temporary housing has a high degree of flexibility and can be transformed and expanded according to actual needs. During the construction process, if there is a need to increase the living space or change the function of the house, it can be quickly remodelled by adding prefabricated components to meet the different needs of the construction workers.

Light steel structure: light steel structure is one of the commonly used structural forms in assembled temporary housing. It has the advantages of light weight, high strength, and fast construction speed, which can meet the rapid construction needs of temporary housing at construction sites. The components of light steel structure can be prefabricated in the factory and assembled on site, making the construction process simple and fast.

Container-type structure: Container-type temporary housing is a house made by transforming and assembling containers. Containers have the characteristics of strong and durable, strong mobility, etc., which are very suitable for use as temporary housing at construction sites. Container-type temporary housing can be combined and spliced according to the actual needs, forming different scales and functions of living space.