Why do more people choose "light steel villas" instead of "brick concrete structures"?

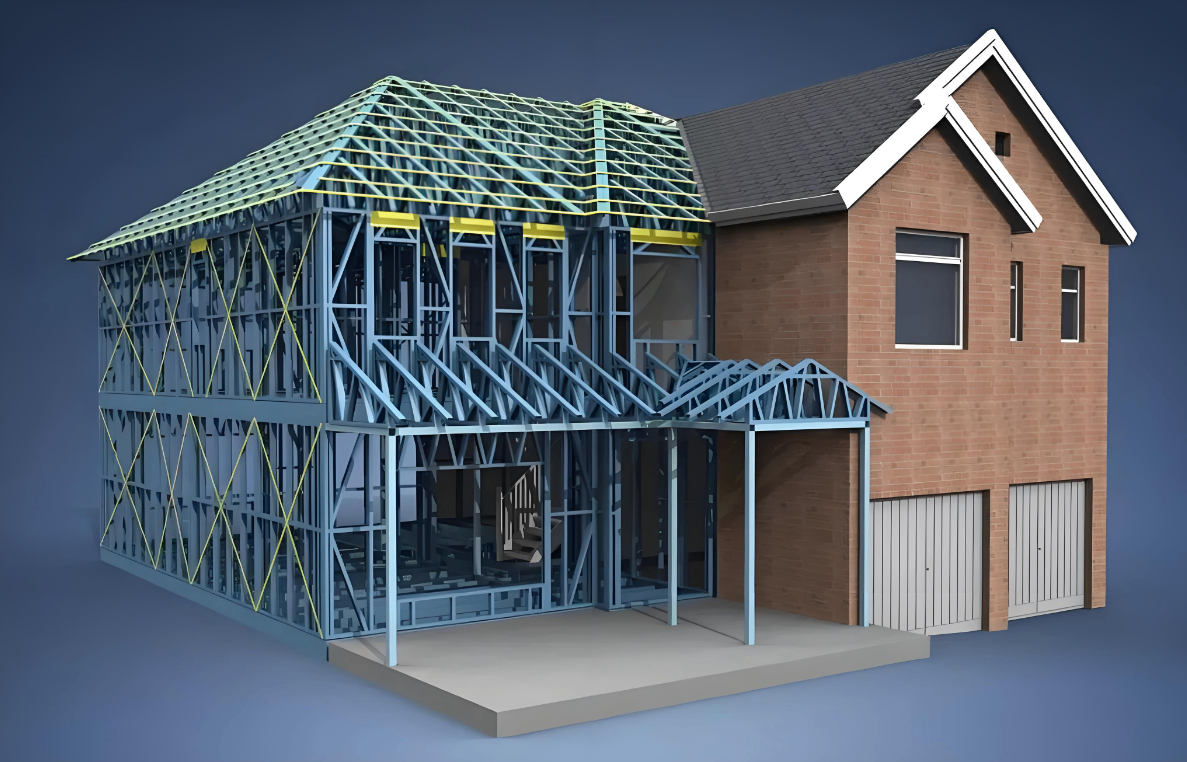

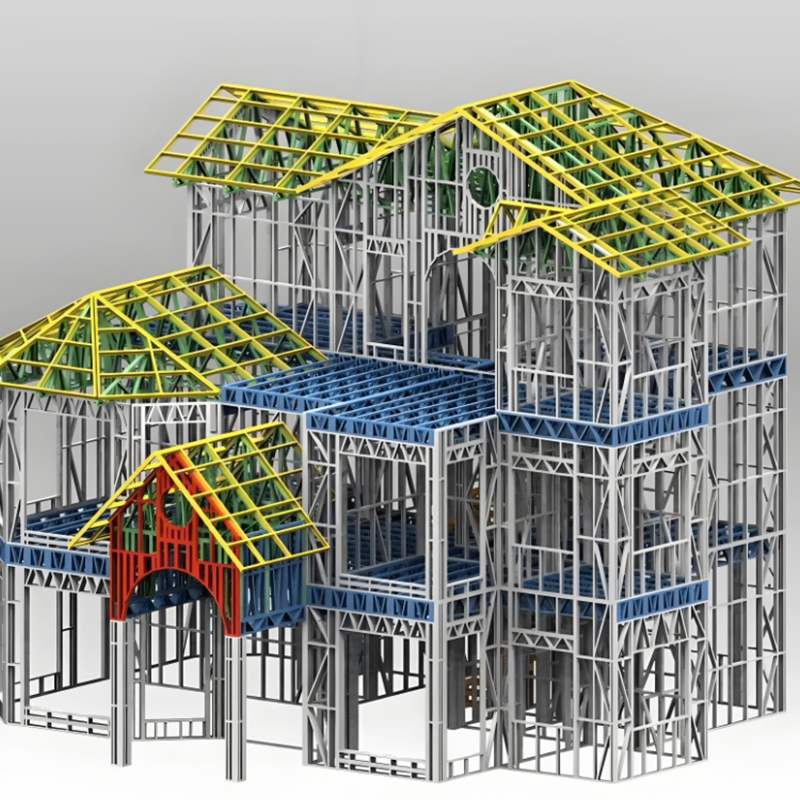

Light steel villas, also known as light steel structure houses, are mainly made of light steel keels synthesized by hot-dip galvanized aluminum steel strips through cold rolling technology. All structural components are made of high-strength galvanized steel to ensure the service life of the house. All structural components are formed by factory precision mechanical assembly line cold pressing, with dimensional accuracy measured in millimeters, which cannot be compared to other structures. Light steel villas and brick concrete structures are currently the two most common ways of building houses in rural hometowns. With the development of rural economy, villagers' housing requirements are no longer just about "being able to live", but also require "comfort, large area" and other requirements. Light steel villas emerged as a result.

Firstly, the structure of light steel villas is more stable. The seismic performance of light steel structures is far superior to traditional concrete and brick concrete residential buildings. At the same time, due to the light weight of light steel structures, the unit area weight is only equivalent to 1/4 of the weight of brick concrete structures of the same area, so its foundation treatment is simple and suitable for most geological conditions. Steel structure residences are no longer as concerned about the harm of termites as traditional structural residences.

Secondly, its service life will be longer than that of brick concrete structures. The technology and product configuration of light steel structures are very mature, with a high degree of industrialization. The galvanized steel plates used in building structures have excellent corrosion resistance and durability, with a service life of 275 years under normal use.

The overall cost of light steel villas is relatively low. Light steel villa structure materials have high strength, thin thickness, and save steel usage. The overall weight of the house is light, only about 1/4 of traditional brick and concrete structures. Greatly reducing transportation and lifting costs, the basic load is also correspondingly reduced, and the basic cost is lowered. The wall, roof truss structure, and inner and outer wall panels of the light steel villa form a sturdy plate rib structure, which greatly improves its ability to resist horizontal and vertical loads, resulting in good seismic and wind resistance performance. It has been proven through experiments that it can withstand earthquakes of 9 ° C and hurricanes of magnitude 12 or above. If brick and concrete houses want to achieve this, a professional team needs to carefully design reinforcement and earthquake prevention measures, which undoubtedly increases the construction cost significantly. Non professionals who are not familiar with the details can easily overlook this expense.

In summary, the choice of building method should still be based on individual needs. If you want to save time and effort, light steel villas are the best choice. Of course, the prerequisite is to find reliable brands and companies. In the market, some unscrupulous light steel practitioners lure homeowners to build light steel structure houses at low prices, and then raise prices during the construction process, requiring much higher prices than the market to complete, which has a negative impact on the light steel industry.