Construction of glass wool

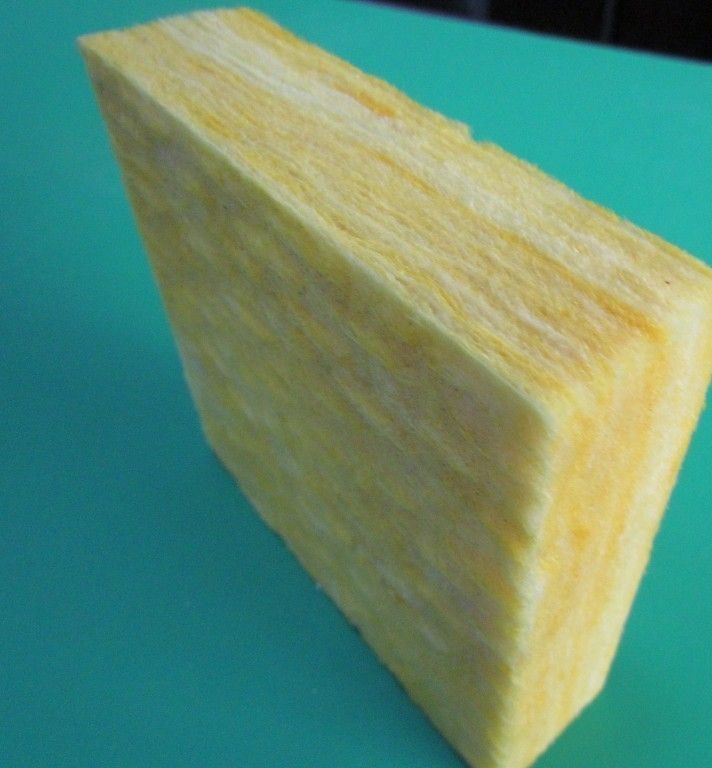

Select glass wool of appropriate specifications and thickness according to design requirements. The common specifications include sheet metal and rolled felt, with a thickness generally ranging from 25 millimeters to 100 millimeters. Prepare supporting fasteners such as anchor bolts, glue, aluminum foil tape, etc. Plastic expansion anchor bolts are generally used, and the length is determined based on the thickness of the insulation layer and the material of the wall. Ensure that the quality of the materials meets relevant standards, and check whether the glass wool is damaged, damp, or not. Accurately measure the dimensions of the construction site using measuring tools, and cut the glass wool according to the measurement results. When cutting, pay attention to the accuracy of dimensions and try to minimize errors. For glass wool in the form of sheet metal, cutting can be done using cutting tools or saw blades; For glass wool in the form of rolled felt, it can be directly unfolded and cut as needed. For substrates with good flatness, glass wool can be installed by pasting. Apply the specialized adhesive evenly on the surface of the base layer and the back of the glass wool, then stick the glass wool onto the base layer and gently press it with your hand to ensure a firm adhesion. For uneven base layers or areas that require higher fixing strength, anchor bolt fixation can be used. Pre drill holes on glass wool, then insert anchor bolts into the holes, and use an electric drill to fix the anchor bolts on the substrate. The spacing and quantity of anchor bolts are determined based on the thickness of the insulation layer and the material of the base layer, generally ranging from 300 millimeters to 600 millimeters. When glass wool needs to be spliced, ensure a tight fit at the joint. Splicing can be done by overlapping, with an overlap length generally ranging from 50 millimeters to 100 millimeters. Use aluminum foil tape to seal the joints and the junction between glass wool and the base layer to prevent air infiltration and heat loss. Aluminum foil tape should be firmly adhered without wrinkles or gaps.

Construct a protective layer on the outside of the glass wool insulation layer to protect it from external environmental influences. Common protective layers include cement mortar protective layer, polymer crack resistant mortar protective layer, aluminum plate or color steel plate protective layer, etc. For the cement mortar protective layer, a layer of interface agent should be applied on the glass wool first, and then the cement mortar should be applied layer by layer. The thickness of each layer should not exceed 10 millimeters, and the total thickness is generally 20 millimeters to 30 millimeters. During the construction process, attention should be paid to compaction and flatness to avoid hollowing and cracks. For the protective layer of polymer anti cracking mortar, evenly apply the anti cracking mortar on glass wool, then lay alkali resistant fiberglass mesh cloth, and apply another layer of anti cracking mortar, with a total thickness of generally 3 to 5 millimeters. The alkali resistant fiberglass mesh cloth should be laid flat, without wrinkles or hollows, and the overlap length should not be less than 100 millimeters. For the protective layer of aluminum or color steel plate, the keel should be installed on the glass wool first, and then the aluminum or color steel plate should be fixed on the keel. The spacing and specifications of the keel are determined based on the material and weight of the protective layer, generally ranging from 600 millimeters to 1200 millimeters.

Check the appearance of the glass wool insulation layer for flatness, no cracks, and no hollowing. The surface should be clean and free of obvious stains and debris. Check the construction quality of the protective layer to ensure it is firm, free from detachment, and undamaged. The color should be uniform and consistent. A thermal performance tester can be used to test the insulation performance of the insulation layer, measuring parameters such as thermal resistance and heat transfer coefficient to ensure that it meets the design requirements. The actual insulation effect of the insulation layer can also be evaluated by comparing the energy consumption of the building before and after insulation. The construction quality of glass wool insulation layer should comply with relevant national standards and specifications, such as the "Code for Acceptance of Construction Quality of Building Energy saving Engineering" (GB 550411). Complete construction documentation should be provided during acceptance, including quality certification documents for materials, construction records, inspection reports, etc.

The above are the construction steps of glass wool in building insulation. During the construction process, it is necessary to strictly follow relevant standards and specifications to ensure construction quality and insulation effect. At the same time, attention should be paid to construction safety, protective measures should be taken, and safety accidents should be avoided.